From the food of the gods to the sweetness of the lovers 4

chocolate-machines.com

chocolate-machines.com

2017-09-29 15:31:20

Prophase process

Packaged cocoa beans are shipped to processing plants around the world.

In a processing plant, the cocoa beans are sorted and baked, and the skins are removed at the same time as they are crushed.

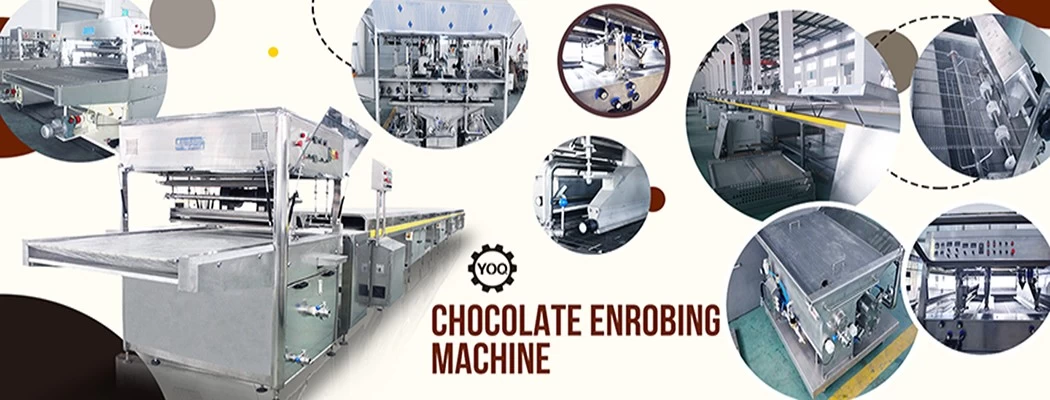

Later, the broken cocoa beans were fed into a huge grinder, and the grinding temperature caused the fat rich cocoa beans to become mushy, which we call cocoa butter, which was cocoa chunks when cooled. YOQ CHOCOLATE MACHINERY provide automatic chocolate enrobing machine.

Press

Cocoa butter contains about 52% of cocoa butter. After putting into the press, the cocoa butter is separated. The remaining residue is cocoa powder, which usually contains 10-20% of cocoa butter.

Forming

Forming

The cocoa block, cocoa butter, sugar, spices, dairy products, etc. in a certain proportion of mixing, into the machine refining. Different refining procedures also lead to differences in chocolate flavor and quality. The refined chocolate is placed in the thermostat and can be molded and packaged after tempering.

Soluble only in mouth, insoluble in hand

This ad explains the characteristics of chocolate very well, and the secret of this is cocoa butter. Cocoa butter is a kind of fat mainly composed of three kinds of fatty acids (oleic acid, stearic acid, palmitic acid). The melting point is 34-36 degrees centigrade, just below the oral temperature, but higher than the body surface (Palm) temperature.

Another characteristic of cocoa butter is that the melting curve is very steep, and the feeling of instant melting in the mouth is wonderful. YOQ CHOCOLATE MACHINERY the most poupular chocolate depositor company china.

There are six kinds of cocoa butter polymorphs (alpha, beta, gamma, beta, beta, beta Rho "), of which the last two kinds of the highest melting point, is also the most stable.

There are six kinds of cocoa butter polymorphs (alpha, beta, gamma, beta, beta, beta Rho "), of which the last two kinds of the highest melting point, is also the most stable.

The "temperature control" mentioned in the "molding" section in the front process controls the formation of these two crystalline patterns. The resulting chocolate has a dense, smooth appearance and a high stability.

We sometimes see that when chocolate is made by hand, the chocolate paste is poured over the Dali stone board. This process is controlled by temperature, and the skill and experience of the operator determine the quality of the chocolate.

Packaged cocoa beans are shipped to processing plants around the world.

In a processing plant, the cocoa beans are sorted and baked, and the skins are removed at the same time as they are crushed.

Later, the broken cocoa beans were fed into a huge grinder, and the grinding temperature caused the fat rich cocoa beans to become mushy, which we call cocoa butter, which was cocoa chunks when cooled. YOQ CHOCOLATE MACHINERY provide automatic chocolate enrobing machine.

Press

Cocoa butter contains about 52% of cocoa butter. After putting into the press, the cocoa butter is separated. The remaining residue is cocoa powder, which usually contains 10-20% of cocoa butter.

Chocolate is added to the cocoa butter cocoa butter extra, cocoa powder is actually excessive. More cocoa powder, in addition to part of the cocoa butter chocolate, mostly into the food industry, has become a variety of cakes and drinks raw materials.

The cocoa block, cocoa butter, sugar, spices, dairy products, etc. in a certain proportion of mixing, into the machine refining. Different refining procedures also lead to differences in chocolate flavor and quality. The refined chocolate is placed in the thermostat and can be molded and packaged after tempering.

Soluble only in mouth, insoluble in hand

This ad explains the characteristics of chocolate very well, and the secret of this is cocoa butter. Cocoa butter is a kind of fat mainly composed of three kinds of fatty acids (oleic acid, stearic acid, palmitic acid). The melting point is 34-36 degrees centigrade, just below the oral temperature, but higher than the body surface (Palm) temperature.

Another characteristic of cocoa butter is that the melting curve is very steep, and the feeling of instant melting in the mouth is wonderful. YOQ CHOCOLATE MACHINERY the most poupular chocolate depositor company china.

The "temperature control" mentioned in the "molding" section in the front process controls the formation of these two crystalline patterns. The resulting chocolate has a dense, smooth appearance and a high stability.

We sometimes see that when chocolate is made by hand, the chocolate paste is poured over the Dali stone board. This process is controlled by temperature, and the skill and experience of the operator determine the quality of the chocolate.

For more information, you can click chocolate forming machine supplier china.