How does chocolate be made?

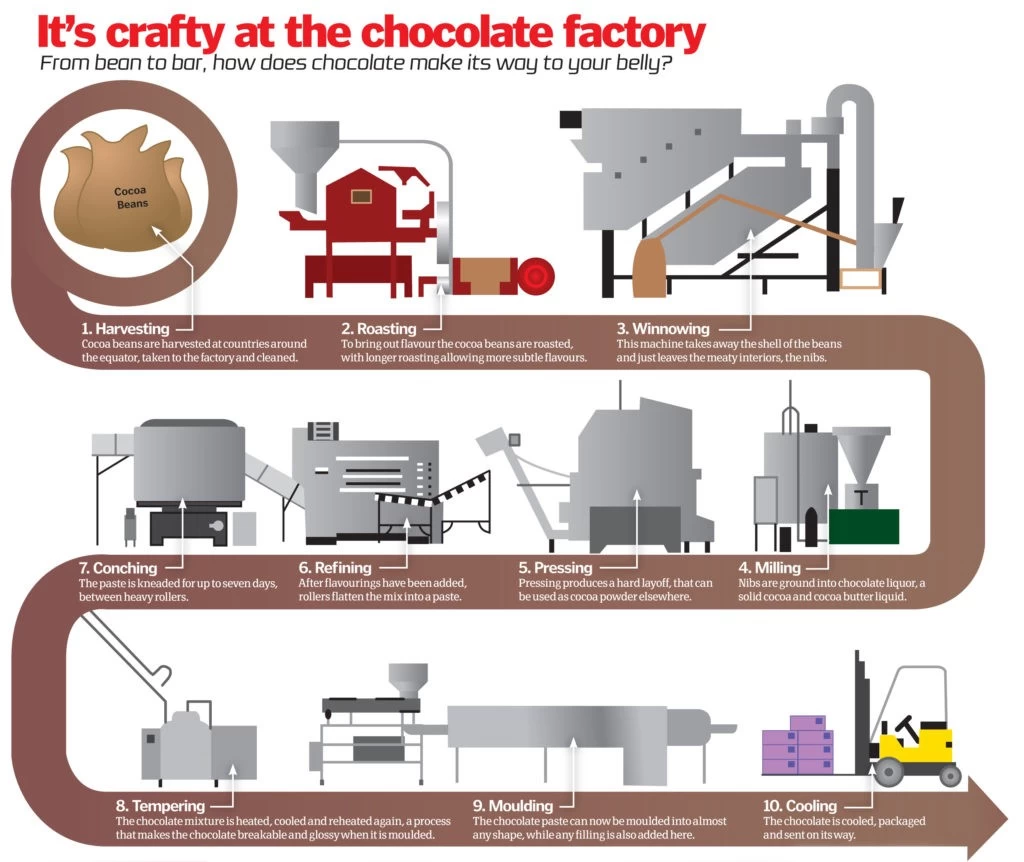

Production of chocolate starts on cocoa tree, where cocoa bean harvesting of cocoa bean crops such as cotton wool is harvested between October and December. Beans are kept between layers of banana leaves for six days so that the pulp can be removed, a method called 'hep', before being dry in the sun, was packed into chocolate making factory is.

Inside the chocolate factory, the beans are heated in a continuous roster because they travel with a conveyor belt. The time of this process varies depending on the required flavor. Once roasted properly, they are broken into small pieces and their brittle shells are removed, leaving only the beefy centers of the beans, 'Nibs', in which the cocoa necessary for chocolate production Has butter. A grinder these nibs are known as gr cocoa liquor in a thick brown liquid, which is the basis of all the chocolate products, which then mixed with different sugar and milk depending on the type of chocolate needed. is. Generally, dark chocolate contains 70% cocoa liquor, while milk and white chocolate contains 30%.

Before the liquid is squash together, this mixture is known as the 'chocolate chocolate crumb' vacuum oven. Then it is grinded between the rollers to improve the silky texture, which. Known as 'conking'. It involves kneading the mixture in giant tanks at about 46 degrees Celsius, which includes very good chocolate for more than a week. The final process is chilly, where the liquid is cooled continuously and heated in a cycle until it is a stable chocolate stability.

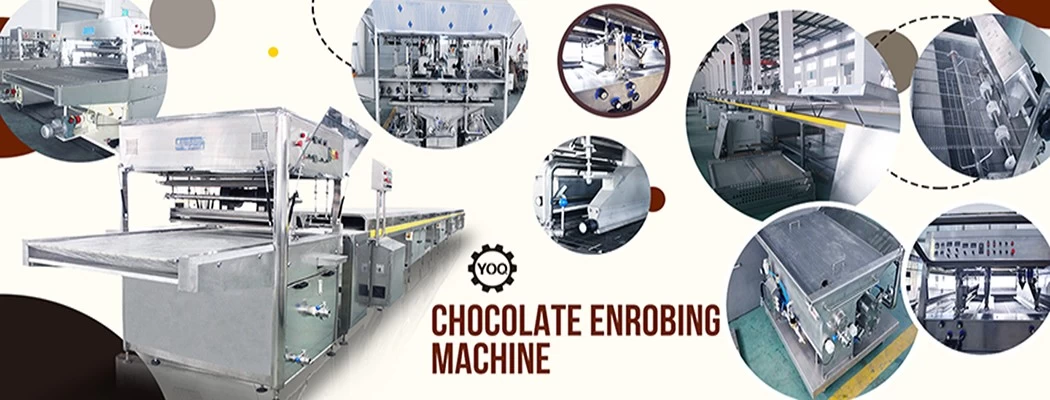

After this phase of the process of making chocolate, the mold can be molded, cooled and wrapped at high speeds to make products like chocolate bars. To make chocolate with a special filling, such as caramel, the interior of the bars pass through a conveyor belt and 'enroob' is done by liquid chocolate before being cooled and wrapped.