3D Printing Car in America Weight reduced and Strength higher 2

Owen Lee

2015-07-09 14:57:09

On this day, Czinger and his team introduced the first 3D print super sports car prototype--Blade.

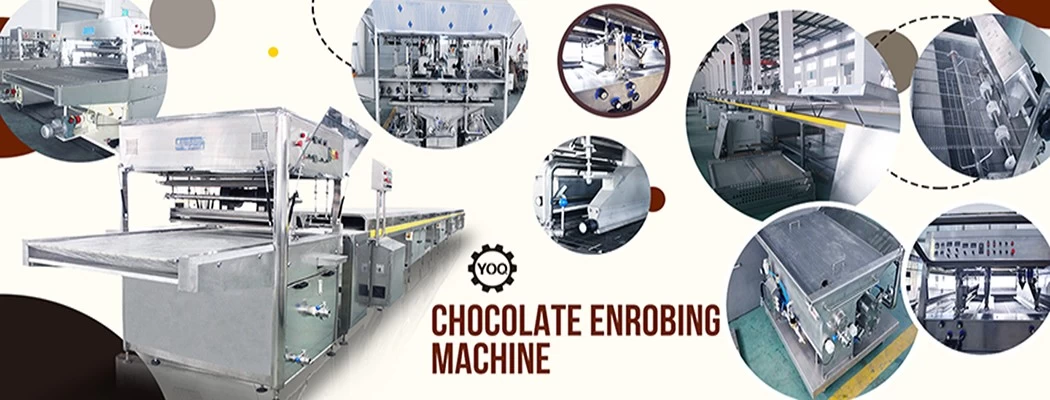

Blade is a true supercar, it can, in just 2.2 seconds to accelerate from 0 to 60 miles per hour (McLaren P1 the figure was 2.8 seconds). It weighs just 1400 pounds, and install a 700-horsepower 4 cylinder dual-fuel internal combustion engines, gasoline or compressed natural gas as fuel can be used. The aluminum chassis by approximately 70 3D print nodes, workers hand-assembled the chassis and it took only 30 minutes. And the chassis itself weighs only 61 pounds. If chocolate can be made of 3D by chocolate coating machine supplier and chocolate coating machine supplier, that will be a brilliant idea.

"The body of the car is composite. "Vara told us. "A cool thing is that the body itself is not structural, so you can use almost any material to manufacture it, even including spandex. This car is one of the most important structural part of the chassis. ”

DM's original plans annual production of 10,000 vehicles this super sports car, available to their potential customers. That's not all, because DM is not just satisfied with this method of making cars. They plan to make this technology available to others. Sales at these super sports car in addition to the tools and techniques they will sell, innovators and entrepreneurs form small teams can create their own micro-factories and according to your own unique design and manufacture their cars. Whether car, truck or other types of super sports car, can be built using the company's proprietary 3D print node technology.

Use this unique 3D printing methods node-type chassis, weight 90%, a higher intensity, and more durable than cars built using traditional technology. Lighter, stronger, more durable, more economical, more environmentally friendly cars, isn't that what a lot of people want to do, so all of a sudden became accessible? is really hard to believe, perhaps, the real limit is not the lack of technology, but the ideas in our head.