3D Printing Car in America Weight reduced and Strength higher 1

Owen Lee

2015-07-09 14:04:22

On June 24, 2015, the O'ReillySolid meeting held in San Francisco, DivergentMicrofactories (DM), founder of CEOKevinCzinger will use a keynote speech that shook the world, his speech is entitled "to the material of automobile production (DematerializingAutoManufacturing)"

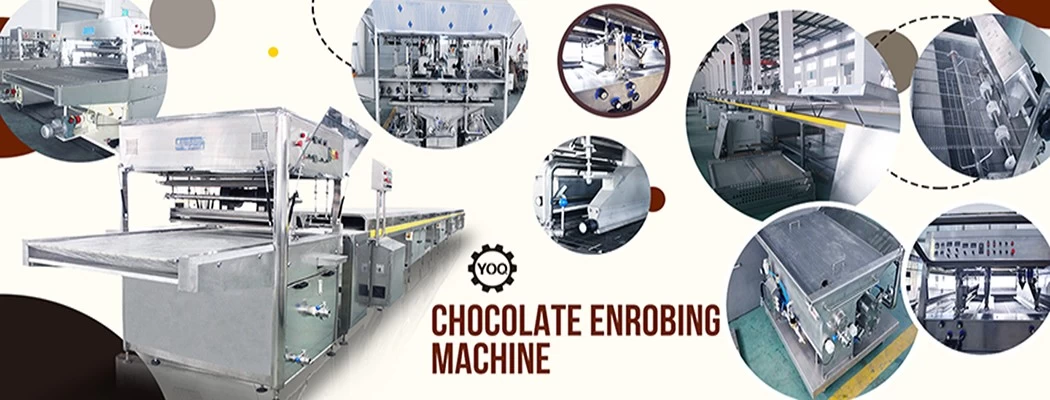

"DivergentMicrofactories will launch a 3D printed parts of the super sports car. It look like an art making by chocolate machine supplier. In addition,good chocolate making machinery china

are also researching 3D printing.

"LMG public relations MannyVara said," it's very light, very fast--it's greater acceleration than McLaren P1, power to weight ratio is twice times the Bugatti Veyron. But the car itself is only part of the story. The company has actually tried to change the car's manufacturing methods, dramatically reducing the traditional automobile manufacturing-related material, energy, pollution and cost. ”

This super sports car known as the Blade (blade), its emissions have only an electric 1/3, and consume only 1/50 of other automotive manufacturing factory capital. 3D printed car from what we see, if LocalMotors Strati different DM manufacturing process quite a few LEGO style.

They are not 3D print the entire vehicle, but a 3D print made of aluminium "node" structure. DM using 3D printing to create elaborate complex of the shape node, ready-carbon fiber tubing connected with it. When all nodes have been printed, several semi-skilled workers chassis can be assembled within a few minutes.

It is understood that the needs of the entire process of constructing the chassis very little funding and other resources, and unlike other automotive manufacturing technology that requires highly skilled and trained workers. DM efforts an important objective is to reduce the environmental impact of pollution and, so far, they seem to have achieved this goal.