Stratasys accelerates the production line of the Chocolate Factory

chocolate-machines.com

chocolate-machines.com

2018-03-09 11:27:52

The chocolate factory in Rotterdam recently integrated the parts printed by 3D into its chocolate production. According to the understanding of the Antarctic bear, the manufacturing efficiency of the company has been greatly improved after the introduction of 3D printing technology.

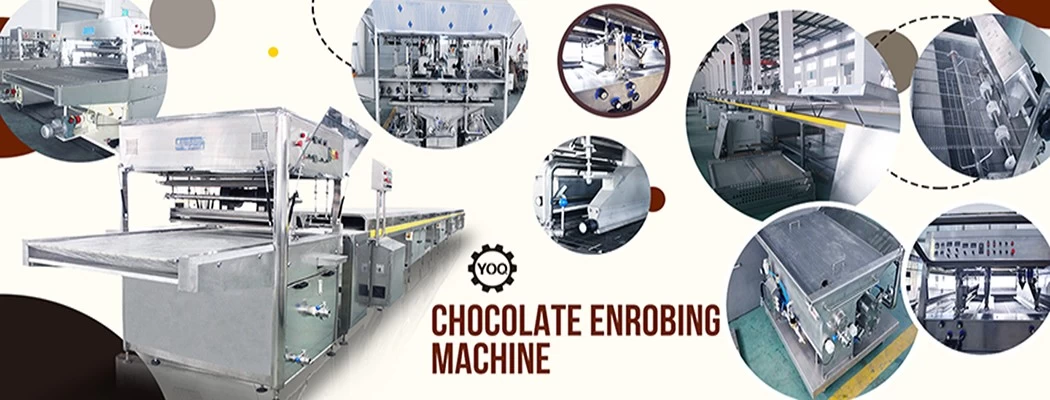

This time 3D printing is not used to print the chocolate itself, but on the chocolate wrapper. Use 3D printing parts to maintain and maintain the smooth operation of the chocolate packaging machine.(snicker chocolate bars making machine)

Before that, the chocolate factory has been worried about a detail in production. Because of an important component of the component - a "small hook" that transports chocolate to a conveyor belt, it sometimes fails. Every time the hooking device meets problems, it must be replaced by hand made parts, which means that some machines are in a state of stagnation for a long time.

To solve the problem of frequent malfunctions, the Chocolate Factory sought help from the 3D service provider VisualFirst in Holland. They suggest using Stratasys nylon 12CF carbon to fill thermoplastic materials and make use of FDM technology to make 3D printing hooks.

VisualFirst's boss, CarlvandeRijzen, explained: "it's vital that the packer is always in a running state, especially during the busy time of Christmas. With Stratasys's 3D printing technology, we can produce customized replacement parts on demand, and their performance is as effective as metal machine parts. We can finish the 3D printing in a week and deliver the production parts to the chocolate factory, which is essential to ensure the normal operation of the production line. "

The hook part withstood all the tests of the machine and failed to run many times. Now, the chocolate factory has replaced the metal parts with the parts printed by 3D.(automatic chocolate coated peanut)

The increase in the production of the chocolate factory since the implementation of the new 3D printing parts has also greatly reduced the cost. According to vandeRijzen, the company saves up to 60% by using 3D printing parts instead of their handmade metal parts.

At present, the Chocolate Factory is working with VisualFirst, making use of 3D printing technology to try the manufacture of the chocolate prototype mold, and will explore more possibilities to integrate 3D printing into its business.(chocolate bean production machines)

Before that, the chocolate factory has been worried about a detail in production. Because of an important component of the component - a "small hook" that transports chocolate to a conveyor belt, it sometimes fails. Every time the hooking device meets problems, it must be replaced by hand made parts, which means that some machines are in a state of stagnation for a long time.

To solve the problem of frequent malfunctions, the Chocolate Factory sought help from the 3D service provider VisualFirst in Holland. They suggest using Stratasys nylon 12CF carbon to fill thermoplastic materials and make use of FDM technology to make 3D printing hooks.

VisualFirst's boss, CarlvandeRijzen, explained: "it's vital that the packer is always in a running state, especially during the busy time of Christmas. With Stratasys's 3D printing technology, we can produce customized replacement parts on demand, and their performance is as effective as metal machine parts. We can finish the 3D printing in a week and deliver the production parts to the chocolate factory, which is essential to ensure the normal operation of the production line. "

The hook part withstood all the tests of the machine and failed to run many times. Now, the chocolate factory has replaced the metal parts with the parts printed by 3D.(automatic chocolate coated peanut)

The increase in the production of the chocolate factory since the implementation of the new 3D printing parts has also greatly reduced the cost. According to vandeRijzen, the company saves up to 60% by using 3D printing parts instead of their handmade metal parts.

At present, the Chocolate Factory is working with VisualFirst, making use of 3D printing technology to try the manufacture of the chocolate prototype mold, and will explore more possibilities to integrate 3D printing into its business.(chocolate bean production machines)