Stratasys help chocolate production, 3D printing give a big help

chocolate-machines.com

chocolate-machines.com

2018-03-01 09:41:20

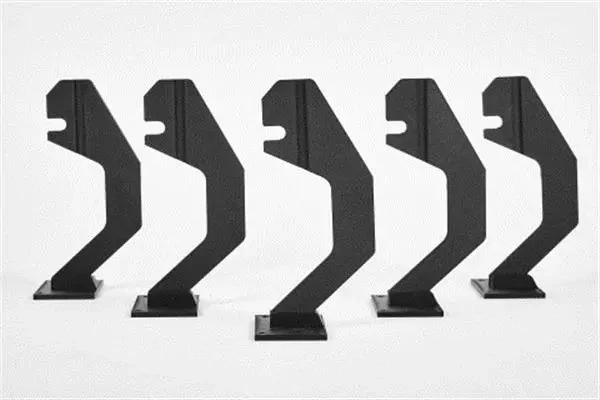

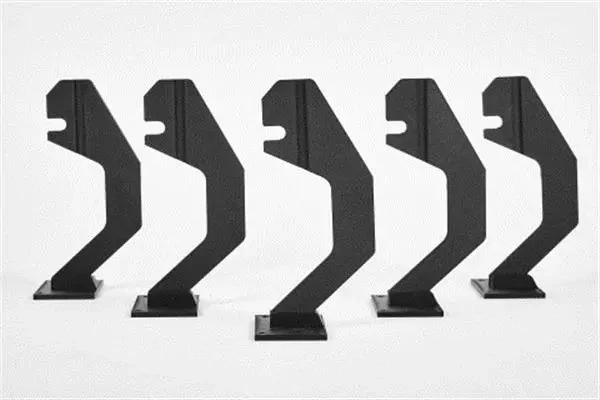

3D printing chocolate packaging machine parts

The Chocolate Factory in Rotterdam recently integrated 3D-printed components into its chocolate production. According to 3D wisdom Bay, the introduction of 3D printing technology, the company's manufacturing efficiency has been greatly improved.

This 3D printing is not used to print the chocolate itself, but on the chocolate packaging machine. Utilizes 3D printing components to maintain and maintain the smooth operation of their chocolate wrappers.

Until then, the chocolate factory has been annoyed with a detail in production. Because an important part of the kit - a "little hook" that carries chocolate onto the conveyor - sometimes fails. Each time the hooking device encounters a problem, it must be replaced by hand-made metal parts, which means that some machines are at a standstill for a long period of time.

The Chocolate Factory in Rotterdam recently integrated 3D-printed components into its chocolate production. According to 3D wisdom Bay, the introduction of 3D printing technology, the company's manufacturing efficiency has been greatly improved.

This 3D printing is not used to print the chocolate itself, but on the chocolate packaging machine. Utilizes 3D printing components to maintain and maintain the smooth operation of their chocolate wrappers.

Until then, the chocolate factory has been annoyed with a detail in production. Because an important part of the kit - a "little hook" that carries chocolate onto the conveyor - sometimes fails. Each time the hooking device encounters a problem, it must be replaced by hand-made metal parts, which means that some machines are at a standstill for a long period of time.

This 3D printing is not used to print the chocolate itself, but on the automatic chocolate decorating machine. Utilizes 3D printing components to maintain and maintain the smooth operation of their chocolate wrappers.

Until then, the chocolate factory has been annoyed with a detail in production. Because an important part of the kit - a "little hook" that carries chocolate onto the conveyor - sometimes fails. Each time the hooking device encounters a problem, it must be replaced by hand-made metal parts, which means that some machines are at a standstill for a long period of time.

Until then, the chocolate factory has been annoyed with a detail in production. Because an important part of the kit - a "little hook" that carries chocolate onto the conveyor - sometimes fails. Each time the hooking device encounters a problem, it must be replaced by hand-made metal parts, which means that some machines are at a standstill for a long period of time.

3D printed parts

To solve the problem of frequent failures, the Chocolate Factory sought help from Visual First, a Dutch 3D service provider. They suggest using Stratasys' nylon 12CF carbon-filled thermoplastic to make 3D printed hooks using FDM technology.

Carl van de Rijzen, owner of Visual First, explains: "It is crucial that the packaging machine is always up and running, especially during such a busy Christmas season, with Stratasys 3D printing technology, where we can produce custom parts on demand, Its performance is as effective as metal machine parts and meets production standards, and we can produce 3D prints in a week and deliver the production parts to the chocolate factory, which is crucial to ensuring the production line is up and running. "

The hooking part survived all the testing of the machine and did not fail multiple runs. Now, the chocolate factory has replaced the 3D printed parts with metal parts.

To solve the problem of frequent failures, the Chocolate Factory sought help from Visual First, a Dutch 3D service provider. They suggest using Stratasys' nylon 12CF carbon-filled thermoplastic to make 3D printed hooks using FDM technology.

Carl van de Rijzen, owner of Visual First, explains: "It is crucial that the packaging machine is always up and running, especially during such a busy Christmas season, with Stratasys 3D printing technology, where we can produce custom parts on demand, Its performance is as effective as metal machine parts and meets production standards, and we can produce 3D prints in a week and deliver the production parts to the chocolate factory, which is crucial to ensuring the production line is up and running. "

The hooking part survived all the testing of the machine and did not fail multiple runs. Now, the chocolate factory has replaced the 3D printed parts with metal parts.

The added volume of production that the chocolate factory has implemented since implementing new 3D printed parts has also led to significant cost savings. According to van de Rijzen, the company can save up to 60% by using 3D printed parts instead of their handmade metal parts.YOQ CHOCOLATE MACHINERY is a biggest chocolate decorating machine wholesales in China.

Currently, the chocolate factory is working with Visual First to try out the manufacture of chocolate prototype molds using 3D printing technology and will continue to explore the possibilities of integrating 3D printing into its business.

Currently, the chocolate factory is working with Visual First to try out the manufacture of chocolate prototype molds using 3D printing technology and will continue to explore the possibilities of integrating 3D printing into its business.

If you want to learn more information about chocolate making machine,please click YOQ CHOCOLATE MACHINERY